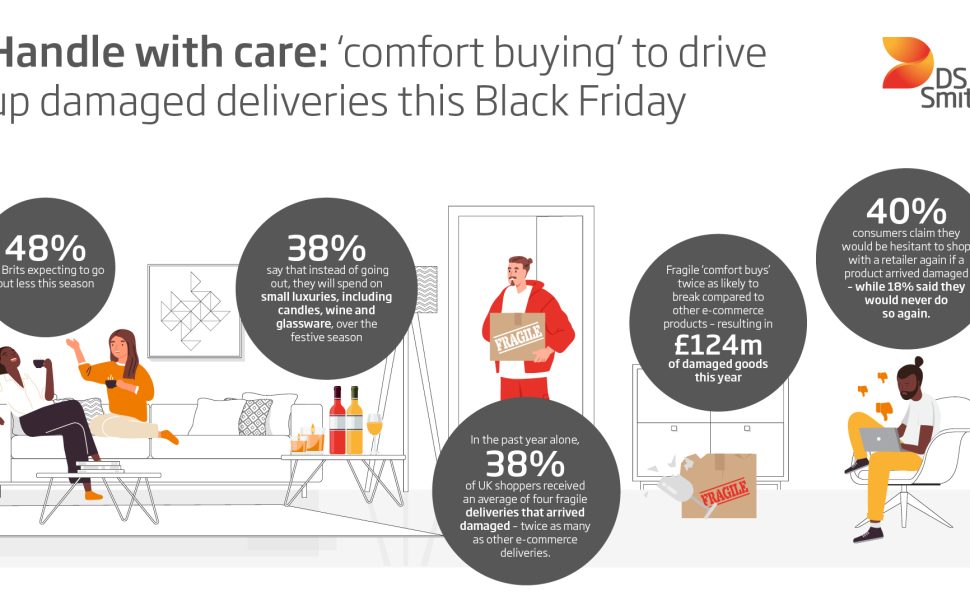

Brits admit they plan to spend more time at home as they continue to feel the pinch of the cost-of-living crisis.

And a new trend of ‘comfort buying’ is also encouraging the nation to cut down on their trips out of the house.

Nearly half of Brits (48 per cent) say they want to spend more time at home as a result of the current financial climate, with four in 10 (38 per cent) admitting that instead of going out, they will spend on small luxuries – rather than bigger expenses – over the festive season.

The research also shows that with the comfort buying ecommerce trend comes an increased risk of damaged deliveries including candles, wine and glassware -as these products are much more likely to be fragile.

And in the past year alone, 38 per cent of UK shoppers received an average of four fragile deliveries that arrived damaged – twice as many as other e-commerce deliveries.

The financial impact of damaged deliveries is significant, with the total spend on damaged fragile goods amounting to a potential £124m.

And the research, commissioned by sustainable packaging company DS Smith, revealed this caused considerable annoyance among 31 per cent of online shoppers who’ve received damaged packages, as well as disappointment (29 per cent) and frustration (24 per cent).

Gavin Mounce, E-commerce Design Manager at DS Smith, said: “No one wants to receive damaged goods – and this Black Friday’s trend for comfort buying shows just how important it is for packaging to withstand the demands of modern shopping so that when people buy fragile things, they’re not left disappointed on delivery, and businesses are not left footing the bill for replacements.

“This is why we put packages through their paces – we drop, shock, crush, shake, and bash them to see how they fare, and what we find is that the answer is not in more packaging, but in more clever packaging.

“That’s the kind of innovation our designers are focused on, as well as finding ways to make every item as circular as possible – designing our wate and pollution from the start, and keeping materials in use for longer.”

The impact of receiving damaged items is substantial, with four in ten (40 per cent) consumers claiming they would be hesitant to shop with a retailer again if a product arrived damaged – while 18 per cent said they would never do so again.

DS Smith’s DISCS™ technology, named after the types of testing it performs (Drop, Impact, Shock, Crush, Shake), replicates a product’s journey to ensure packaging is fit for purpose so that the product is safe while in transit and avoids excess packaging.

To ensure that sustainability is built into the design of DS Smith’s packaging, it has trained over 700 of its designers to use its circular design principles, enabling designers to consider different stages of a product’s lifecycle — including creation, maintenance, and recovery.

More information on the DISCS™ testing can be found here and details on DS Smith’s Circular Economy Leadership can be found here. DS Smith’s Circular Design Principles are explained here.